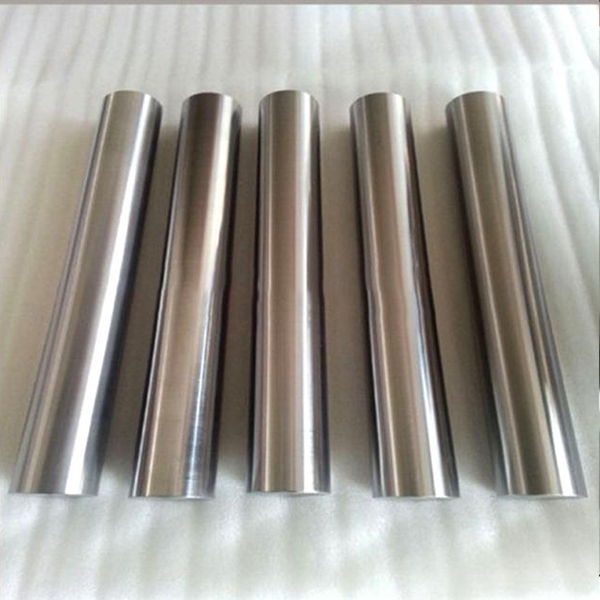

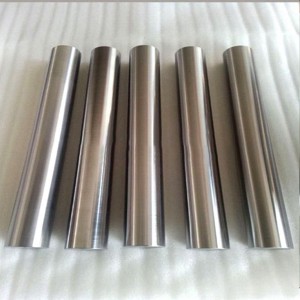

Astm B392 r04200 Type1 Nb1 99.95% Niobium Rod Pure Niobium Round Bar Mutengo

Zvimiro zveChigadzirwa

| Zita rechigadzirwa | ASTM B392 B393 High Purity Niobium Rod Niobium Bar ine Mutengo Wakanakisisa |

| Kuchena | Nhamba ≥99.95% |

| Giredhi | R04200, R04210, R04251, R04261, Nb1, Nb2 |

| Zvakajairika | ASTM B392 |

| Saizi | Saizi yakagadzirwa |

| Nzvimbo yekunyunguduka | 2468 degrees sendigirii |

| Pokufashaira | 4742 degrees sendigirii |

| Zvakanakira | ♦ Kuwanda Kwakaderera uye Simba Rakanyanya ♦ Kuramba Kuora Kwakanaka |

| ♦ Kuramba kwakanaka kunokonzerwa nekupisa | |

| ♦ Isina magineti uye Isina chepfu | |

| ♦ Nzvimbo yekunyunguduka kwepamusoro, inodzivirira ngura zvakanaka, inofambisa zvakanaka zvinhu uye mamwe maitiro akasiyana. |

| Kuumbwa kwemakemikari (%) | ||||||||||||

| Nb | Fe | Si | Ni | W | Mo | Ti | Ta | O | C | H | N | |

| Nb1 | Zvasara | 0.004 | 0.002 | 0.002 | 0.004 | 0.004 | 0.002 | 0.07 | 0.015 | 0.005 | 0.0015 | 0.003 |

| Nb2 | Zvasara | 0.02 | 0.02 | 0.005 | 0.02 | 0.02 | 0.005 | 0.15 | 0.03 | 0.01 | 0.0015 | 0.01 |

Kushivirira Kwechiyero

| Dhayamita(mm) | Kushivirira kwedhayamita (mm) | Kureba (mm) | Kushivirira Kwehurefu (mm) |

| 3.0-4.5 | ±0.05 | 200-1500 | +5 |

| >4.5-6.5 | ± 0.10 | 200-1500 | |

| >6.5-10.0 | ± 0.15 | 200-1500 | |

| >10-16 | ± 0.20 | 200-2000 | |

| >16-18 | ±1.0 | 200-2000 | |

| >18-25 | ±1.5 | 200-2000 | |

| >25-40 | ±2.0 | 200-2000 | |

| >40-50 | ±2.50 | 200-2000 | |

| >50-65 | ±3.00 | 200-2000 | |

| >65-150 | ±4.00 | 200-1000 |

Zvinodiwa paMichina (Mamiriro ezvinhu akavharirwa)

| Giredhi | Simba rekudhonza δbpsi (MPa), ≥ | Simba rekupa δ0.2, psi (MPa), ≥ | Kureba kwegeji ye 1"/2" kureba, %, ≥ |

| RO4200-1 RO4210-2 | 18000 (125) | 12000 (85) | 25 |

Kushandiswa

♦ Indasitiri yemagetsi, Chemistry, Electronical, Pharmaceutical industry.

♦ Simbi, Ceramics, Electronics, maindasitiri esimba renyukireya uye tekinoroji ye superconductor.

♦ Zvishongo zvesimbi zvakapfava, zvakanyungudutswa uye zvinosanganisa simbi.

♦ Inoshandiswa zvakanyanya mukugadzira mhando dzakasiyana dzesimbi yesimbi, chisanganiswa chekupisa kwakanyanya, girazi remaziso, chishandiso chekucheka, zvinhu zvinogadzira zvinhu zvakawanda uye mamwe maindasitiri.

Nyora meseji yako pano woitumira kwatiri