Sechikamu cheMuunganidzwa Chakaposhwa Pamusoro Nb Pure Niobium Metal Niobium Cube Niobium Ingot

Zvimiro zveChigadzirwa

| Zita rechigadzirwa | Ingot yakachena yeNiobium |

| Zvinhu | Niobium yakachena uye niobium alloy |

| Chiyero | Sekureva kwechikumbiro chako |

| Giredhi | RO4200.RO4210,R04251,R04261 |

| Maitiro | Yakamonerwa nechando, Yakamonerwa nekupisa, Yakaburitswa |

| Hunhu | Nzvimbo yekunyunguduka: 2468℃ Nzvimbo yekufashaira: 4744℃ |

| Kushandiswa | Inoshandiswa zvakanyanya muminda yemakemikari, yemagetsi, yendege uye yemuchadenga |

| Zvimiro zveChigadzirwa | Kuramba Kuora Kwakanaka Kuramba kupisa |

Niobium Grade & musanganiswa

| Giredhi | ||||

| RO4200 | RO4210 | RO4251 | RO4261 | |

| Zr | 0.02 | 0.02 | 0.8~1.2 | 0.8~1.2 |

| Ta | 0.1 | 0.2 | 0.1 | 0.5 |

| Fe | 0.005 | 0.01 | 0.005 | 0.01 |

| Si | 0.005 | 0.005 | 0.005 | 0.005 |

| W | 0.03 | 0.05 | 0.03 | 0.05 |

| Ni | 0.005 | 0.005 | 0.005 | 0.005 |

| Mo | 0.010 | 0.010 | 0.010 | 0.05 |

| Hf | 0.02 | 0.02 | 0.02 | 0.02 |

| B | 0.0002 | - | 0.0002 | - |

| Al | 0.002 | 0.005 | 0.002 | 0.005 |

| Be | 0.005 | - | 0.005 | - |

| Cr | 0.002 | - | 0.002 | - |

| Co | 0.002 | - | 0.002 | - |

| Nb | Kuenzana | Kuenzana | Kuenzana | Kuenzana |

Zvinodiwa zvemakanika (mamiriro akavharirwa)

| Giredhi | Simba rekusimba δb psi (MPa), ≥ | Simba rekupa δ0.2, psi (MPa), ≥ | Kureba kwe 1"/2" kureba kwegeji, %, ≥ |

| RO4200-1 RO4210-2 | 18000 (125) | 12000 (85) | 25 |

Zvigadzirwa zvese zveNiobium zviripo

| Zita rechigadzirwa | Giredhi | Zvakajairika |

| Niobium ingot | RO4200, RO4210, RO4251, R04261 | ASTM B392, 393, 394 ASTM B708, 365, 521 |

| Bhawa reNiobium | ||

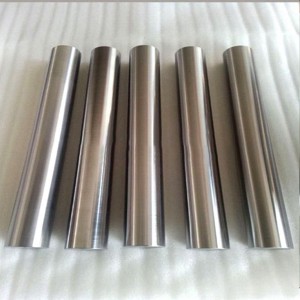

| Chubhu yeNiobium | ||

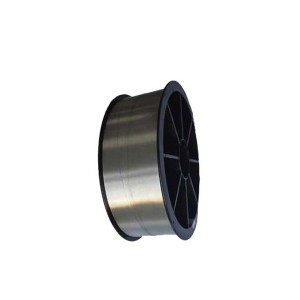

| Waya yeNiobium | ||

| Pepa reNiobium | ||

| Niobium crucible | ||

| Chinangwa cheNiobium | ||

| Zvikamu zveNiobium |

Chinhu

1. Giredhi: Nb1, Nb-Ti, RO4200, RO4210

2. Saizi: Dia 1mm min.

3. Kuchena: 99.95%

4. Chitupa: ISO9001:2008, ISO14001:2004, CE

5. Chimiro: tsvimbo, bhaa, ndiro, jira, foil, chubhu, waya, crucible, nezvimwewo.

6. Mitemo: ASTM B392, 393, 394...

7. Mashandisirwo: Zvinhu zveSemiconductor, vacuum coating, matireyi ekupisa nezvikepe, mashandisirwo akakosha emakemikari.

8. Chinhu Chinogadzirwa: Nzvimbo yekunyunguduka yakanyanya, kuwanda kwakanyanya, kuramba kuoxidation pakupisa kwakanyanya, kushanda kwenguva refu, kuramba ngura.

Kushandiswa

1. Indasitiri yemagetsi Indasitiri yemakemikari, yemagetsi, yemishonga.

2. Kune simbi, zviumbwa zvesimbi, zvemagetsi, maindasitiri esimba renyukireya uye tekinoroji ye superconductor;

3. Kune ma ingots emhando yepamusoro, akaumbwa nesimbi uye alloying agents.

4. Inoshandiswa zvakanyanya mukugadzira mhando dzakasiyana dzesimbi yesimbi, chisanganiswa chekupisa kwakanyanya, girazi remaziso, chishandiso chekucheka, zvemagetsi nezvinhu zve superconducting nezvimwe zvinhu.